Hyperspectral Machine Vision

Automated Optical Sorting and Quality Control

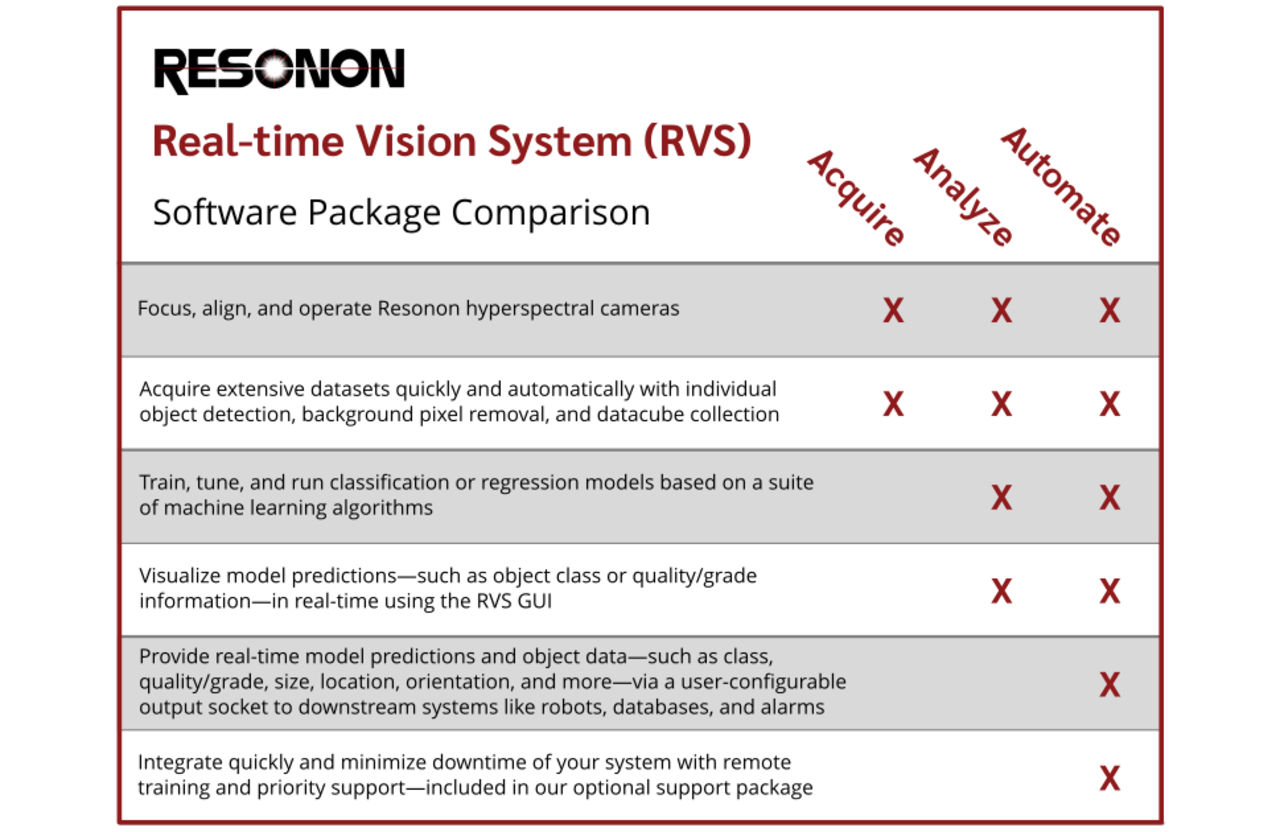

RVS Software

Real-time Vision System

Resonon's RVS software is used in industrial installations at leading companies in food production, manufacturing, and recycling. There are three RVS versions:

RVS - Acquire, RVS - Analyze, and RVS - Automate (version details)

The videos demonstrate how quick and easy it is to use RVS in your optical sorting, grading, or quality control system, without any knowledge of hyperspectral imaging or machine learning.

For a benchtop-sized system capable of running RVS (for laboratories or industrial feasibility tests), see our SpectralSight™ System.

Machine Vision System Implementation Process

Our machine vision implementation process typically involves the following steps:

1. Feasibility Study (typically no cost)

- You send samples and we provide you with a feasibility report.

- We collaborate to define key parameters, including: conveyor dimensions, speed, object size, resolution, and desired outputs (e.g., sorting robot integration).

2. Pilot Study (if necessary)

- After a successful feasibility study, we provide estimates for a pilot study and the implemented system.

- Preferably, the pilot study occurs at your site to replicate the actual operating environment.

3. Full System Implementation

- After a successful pilot study, we can provide full system implementation: permanent fixtures, lighting, software development, and integration with other equipment (e.g., sorting robots)

- Flexible Integration Options: full integration, collaboration with you or your system integrator, or a recommendation for a suitable integrator.

Contact us to discuss getting started with your samples.

RVS Software Packages

- RVS - Acquire enables object detection and datacube creation for each object, all automatically

- RVS - Analyze adds a full suite of machine learning algorithms to classify objects or quantify variables via regression

- RVS - Automate adds a user-configurable output socket, enabling integration with downstream systems (e.g., picking robots, air-jets, databases, etc.)

Hyperspectral Imaging Camera Options

Resonon offers hyperspectral imaging cameras that scan wavelengths from the near-ultraviolet (NUV), through the visible (VIS), to the near-infrared (NIR).

Our team will help you identify the system best suited to your needs. Please contact us for further information.

Spectral Range (nm)

420 - 980

Spectral Resolution - FWHM (nm)

3.1

Spectral Channels

224

Spatial Pixels

720

Max Frame Rate (fps)

585

Weight, w/o lens (kg)

0.64

Spectral Range (nm)

900 - 1700

Spectral Resolution - FWHM (nm)

8.8

Spectral Channels

168

Spatial Pixels

320

Max Frame Rate (fps)

508

Weight, w/o lens (kg)

2.95

Frequently Asked Questions

What types of problems can hyperspectral machine vision help me solve?

Hyperspectral machine vision is useful in automated sorting

applications. Automated sorters typically use hyperspectral imaging to

determine one of two types of information:

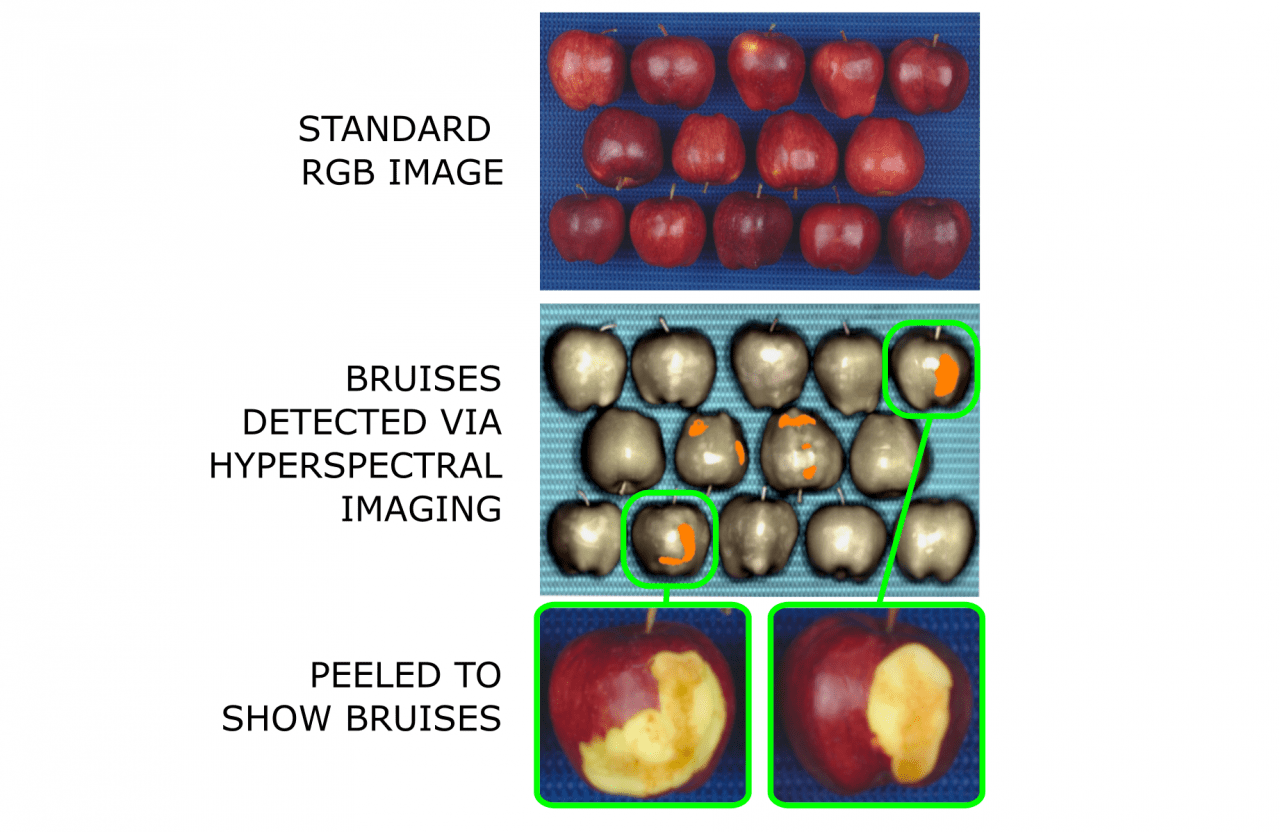

- Classification/Identification: Category prediction (e.g., conforming or non-conforming product, product or foreign material, type of plastic, bruised or unbruised apple)

- Grading/Regression: Determines the state of a product (e.g., ripeness of a fruit, moisture content in a baked food product, percentage of a specific material in a mixed group, deviation from a nominal value such as product color variance)

What components are typically included in a hyperspectral machine vision system?

Resonon’s machine vision systems are generally customized to

fit the application, but typically have the following components:

- A hyperspectral camera to collect the raw hyperspectral data. The type of camera depends on the what the system needs to ‘see’.

- Data analysis software such as Resonon’s RVS (Real-time Vision System) software. The software enables training, visualization of the data, and converts the raw data to useful information. The software also provides output to, for example, control robots or air jets used for sorting the product based on the RVS results.

- A lighting system to illuminate the product.

- A white reference (calibration system). Lighting systems change their output, both overtime and due to other factors like temperature. Regularly calibrating the illumination system with a known white reference panel eliminates the effects of lighting instabilities.

- A conveyor belt. Hyperspectral cameras collect imagery one line at a time, and therefore the product of interest must be translated past the hyperspectral camera.

- An encoder to enable the product location to be accurately tracked and correlated with the hyperspectral data.

- An enclosure is often included to control dust and to keep unwanted sources of light, such as sunshine through a window, from impacting the data.

How does Resonon’s machine vision system interface or integrate with factory automation systems? What kind of outputs does it provide?

The Real-time Visions System (RVS) software runs a socket server output. The server

broadcasts a customizable data signal for each object detected by the system. Data

that can be included for each object are encoder stamps, time stamps, pixel

coordinates mapped to belt geometry, classification results, shape, size, and

orientation.

This output is fully customizable and configurable to drive additional hardware downstream, such as picking robots, air-jet sorters, etc. The socket server output is designed to be simple to configure, either by an end user with some software experience or by a Resonon software engineer.

How do I teach a hyperspectral camera to detect good and out-of-spec products?

Resonon’s Real-time Vision System (RVS) software

makes it easy to train the machine vision system. RVS provides tools for

collecting and organizing training data, visualizing results, training a model,

and updating previously trained models. Multiple machine learning models are

available with metrics to quickly optimize the system for accuracy and speed.

How does a Resonon machine vision system handle changes in product shape, texture, color, etc.?

Resonon’s RVS software can calculate shape statistics

(e.g., area, perimeter, orientation) but it does not use shape for

classification. If your application would benefit from shape-based

classification, Resonon can develop a custom application.

Texture indicates variable spectral response and

can therefore be a challenge or an asset, depending on how the system is

programmed. Resonon has developed models that leverage texture data, but most

simple models ignore it.

Color is spectrum, so it is a

critical parameter. If the product color is variable, the system needs to be

trained on the complete range of color it could encounter.

What is the maximum number of parts that a hyperspectral machine vision system can inspect per minute?

It depends on factors like object size, product

density, complexity of inspection algorithm, and belt speed. The maximum camera

line speed (also known as Max Frame Rate) is approximately 500 lines per

second. Using the number of spatial pixels of the camera (see our camera

specifications table), you can calculate the number of pixels imaged

per second. Nine pixels per object is a reasonable baseline for estimating the

smallest detectable object. Using the number of pixels imaged per second and 9

pixels per object as a minimum, you can estimate a theoretical maximum

throughput. Throughput achieved in practice is generally less than the

theoretical maximum.

How small of a defect or difference can hyperspectral machine vision systems detect?

Factors such as belt speed, belt width, camera

properties, objective lens selection, camera position, and lighting all

influence the minimum detectable defect size. Generally, the system can

confidently detect defects or differences spanning approximately 9 pixels (3 ×

3) per object of interest.

What is the maximum conveyor belt speed that a Resonon machine vision system can inspect?

Resonon hyperspectral imagers are line-scan devices, so

maximum belt speeds are closely linked to the size of the objects or defects

under inspection. Other important factors are the difficulty and accuracy

requirements of the inspection task and the physical constraints of the camera

and lighting system.

The formula for calculating along-track (in the direction of belt travel) spatial resolution of the hyperspectral camera as a function of belt speed is as follows: \[Spatial\,Resolution\,(mm)= {{Belt\,Speed\,(meters/minute)} \over Frame\,Rate\,(lines/second)}*{1000\over60}\]

High-speed imagers scan at approximately 500 lines per

second. At a belt speed of 16 m/min (~50 ft/min), the along-track spatial

resolution of the camera is 0.5 mm. The machine vision system can generally detect

objects or defects that are 9 pixels (3 x 3) in size. For this example, an

object or defect that is 1.5mm in size is detectable. Reach out to a Resonon

application specialist for an estimate specific to your system.

Can Resonon’s machine vision system see through packaging, water, containers, or other materials?

The system can see through some materials and,

depending on the material and the spectral range of the camera, may also be

sensitive to some depth. We recommend testing

samples to determine if the technology meets your needs. Please

contact a member of the Resonon Sales Team to have

your samples tested at our facility.

How deep into objects can the hyperspectral camera see?

Like many imaging technologies, hyperspectral

imaging is primarily sensitive to surface characteristics. However, these

systems can detect some sub-surface characteristics, like fruit bruising and

fruit ripeness. See our bruised apples application example.

Is Resonon’s machine vision system waterproof or dustproof?

You will want an enclosure to protect your

system. Some components of the system are not waterproof and are only partially

dustproof. Enclosures are available off the shelf, and Resonon has experience

designing and procuring custom enclosures if needed.

How do changes in lighting in the factory affect Resonon’s machine vision system?

The system requires specialized, controlled

lighting that is enclosed or otherwise shielded from external light sources in

the facility.

Do you sell turnkey machine vision solutions for factory lines?

We do not sell turnkey systems for installation

into factory lines, as machine vision installations generally require some

degree of customization. We work with you to determine which aspects of the

integration your team has the expertise to manage, and support you in

completing the rest.

That said, we do sell turnkey hyperspectral imaging systems for pilot projects. Our SpectralSight System is the ideal tool for running a pilot project in your facility. It makes developing, training, and testing our machine learning models on your products simple without any disruption to your manufacturing line.

Which hyperspectral camera do I need for my application?

The spectral signatures of the objects or defects in your

application will determine which wavelengths are important, and these

signatures can be difficult to identify without testing. Please contact the Resonon Sales Team if you’d

like to have samples tested.

Can I self-install a Resonon machine vision system?

No — a Resonon machine vision expert will

install and set up the system.

Do you offer in-person training on how to use a Resonon machine vision system?

Yes. A Resonon machine vision expert will be

on-site for installation, and in-person training is typically conducted

following initial setup.

Can I run a sample test to see if Resonon’s machine vision system meets my needs?

Yes — Resonon is happy to provide proof-of-concept testing on

your samples.

Please contact the Resonon Sales Team and tell us

about your intended application.

Application Example: Detecting Apple Bruises

A Pika IR+ hyperspectral camera was used to scan apples, some of which were purposefully bruised pre-scanning.

Resonon’s Spectronon software was used to classify the bruises. Peeling the skin shows the bruising, undetectable in a standard RGB image.

Contact Us

Click below and our hyperspectral experts will contact you soon.

Complete Hyperspectral Imaging Solutions

Contact

Resonon Inc.123 Commercial Drive

Bozeman, MT 59715 USA