Getting Started with Hyperspectral Machine Vision Systems

By Mike Stebbins, COO & Optomechanical Engineer - January 10, 2024

Hyperspectral machine vision is useful in scenarios that

call for automatic inspection, analysis, and action on the factory floor, such

as automated sorting. Automated sorters typically use hyperspectral imaging to

determine one of two types of information:

- Classification: Category prediction (e.g., acceptable vs. not acceptable, product vs. foreign material, specific type of plastic, bruised vs. unbruised fruit).

- Regression: Quantity prediction (e.g., ripeness, moisture content, percentage of a material in a mixed group, deviation from a nominal value such as product color).

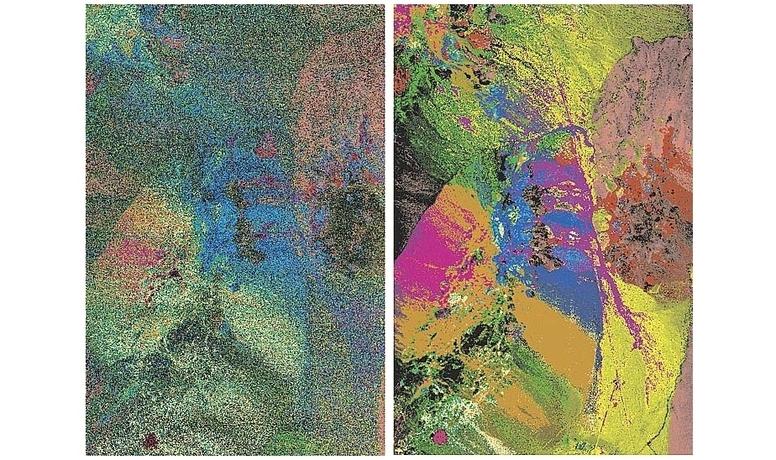

Hyperspectral machine vision systems collect spectral data

from the objects under inspection and then compute the classification or

regression on a per-pixel or per-object basis. Depending on the application, the

results might show information such as defects in the product, mixture ratios,

or debris interspersed among good product.

The results obtained can be translated to meet the input requirements of the factory system, from triggering a subsequent process to alerting an operator to an issue. For example, the system can provide specific coordinates for a picking robot or air jet sorter that will separate the classified products.

Moreover, Resonon’s machine vision software is

easy to use.

See the video above for a short demonstration.

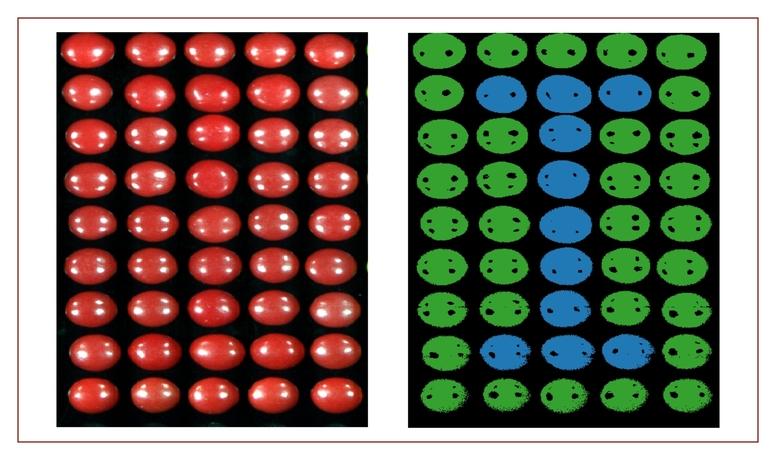

The software’s algorithms learn to detect acceptable and

out-of-spec products using training data. The training data are efficiently assembled,

and multiple algorithms can be tested for optimal performance. By applying

different models, you can determine a solution that meets your application-specific

requirements.

How Shape, Texture, Color, and Orientation Impact Hyperspectral Machine Vision System Outputs

Color difference is another way of saying spectral change. Spectral

differences, even those too small to be detected by the human eye, are what hyperspectral imaging systems use to

differentiate between objects. Object shape statistics (e.g. area, perimeter,

orientation) can also be calculated with Resonon’s RVS software, but these

statistics do not provide the primary information used by the hyperspectral

machine vision system to make predictions.

Product spectral variation and texture generally create

challenges for color-sensitive machine vision systems. A hyperspectral machine

vision system can overcome this challenge by ensuring that the training data

for the classification model include samples encompassing all the spectral

variation and texture that the system will encounter in production. In some

cases, product texture can even be an asset that improves classification accuracy

in a hyperspectral system.

More Questions

Review our extensive FAQ section on the Machine Vision page for more information on Resonon’s machine vision

system.

Resonon’s machine vision experts are also happy to discuss the details

of your application to help you determine whether hyperspectral machine vision is

suitable.

Contact us

Contact us

Technical

Signal-to-Noise Ratio (SNR) in Hyperspectral CamerasDecember 8, 2023

Basics

An Introduction to Hyperspectral ImagingOctober 4, 2023

Contact Us

Click below and our hyperspectral experts will contact you soon.

Complete Hyperspectral Imaging Solutions

Contact

Resonon Inc.123 Commercial Drive

Bozeman, MT 59715 USA