Using Hyperspectral Imaging to Sort Textiles

92M Tons

Textiles into landfills annually (global)10%

Textile production contribution of global carbon emissions

Textiles into landfills annually (global)10%

Textile production contribution of global carbon emissions

Challenge

According to the U.S. Environmental Protection Agency, 17 million

tons of textile were generated in the US in 2018. Two and a half million tons

were recycled, three million tons were combusted for energy, and eleven million

tons were sent to the landfill1. Thus, about 65% of waste textiles

end up in landfills.

Textile waste is increasingly recognized as a significant

environmental problem that currently does not have clear solutions. In 2020,

the EU adopted a new circular economy plan2. Part of this plan

focuses on textiles, with a goal of all textile products placed on the EU

market being long-lived and recyclable by 2030. The commission is also

proposing targets for recycling of textile waste and supports a legislative

target for textile recycling and reuse3. It is a multi-pronged and

incremental approach that also includes regulating the manufacturing industry4.

Recycling will be a key component of reducing textile-related environmental

impacts and it requires dependable sorting technology.

Recycling Solution

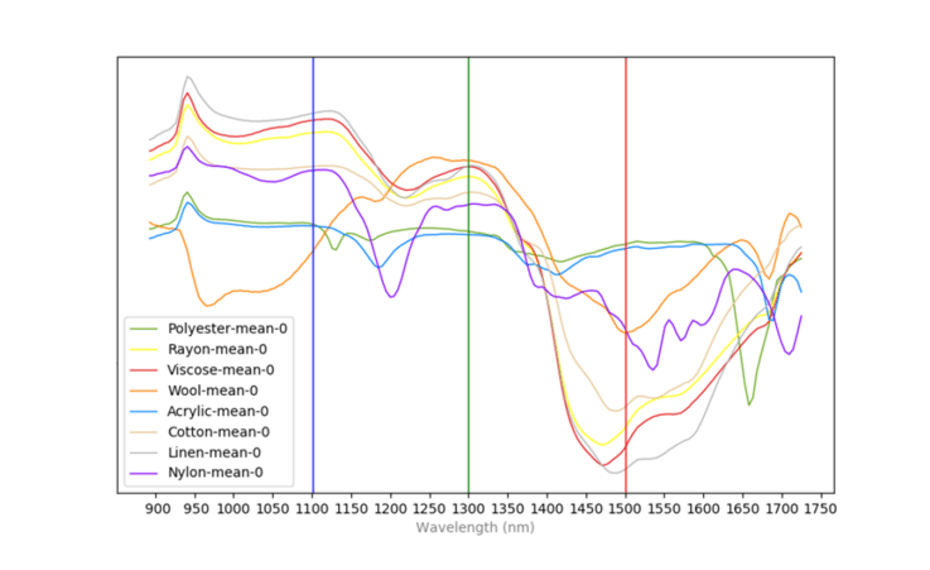

Our internal feasibility study shows that hyperspectral

imaging provides sufficient contrast to sort most textiles based on their

spectral signature in the NIR spectral range (from 900 to 1700 nm), mostly

irrespective of their visible color. Therefore, hyperspectral imaging has the

potential to be a crucial technology for sorting textiles for recycling.

Application Overview

We scanned two dozen textile samples of natural, synthetic,

and blended fibers. We then refined several data pre-processing steps and chose

classification algorithms to optimize the system’s ability to distinguish

between various textiles.

After model training, we successfully classified various

chopped textile fibers and a few full clothing items in real-time on our

experimental conveyor station. See the video below.

Equipment Used

We used Resonon’s Real-time Vision System (RVS)

software and a Pika IR to scan

textile samples. Scanning was completed with our SpectralSight™ System using two 4-fixture halogen lighting units.

Results

Synthetic fibers are the easiest to distinguish due to their

well-defined and unique chemical bonds, which lead to characteristic spectral

signatures that are readily classified by machine learning algorithms.

Natural fibers such as cotton and linen are made of similar

cellulose building blocks. Their spectral signatures are distinct from the

synthetic fibers but more similar with respect to each other.

There are several hybrid textiles, such as viscose and

rayon, that are chemically processed fibers from natural sources. Since they

are made of natural fibers (wood or other plant-based fibers) their spectral

signatures are closer to those of cotton and linen.

Wool has a unique spectral signature with a broad dip in

reflectance around 1000 nm that was not present in any other fibers. As a

result, wool is easily sorted from other fabrics.

The video below shows RVS classifying chopped textile fibers

and a few full clothing items in real-time.

Despite having never seen the clothing items prior to this

test, the system unambiguously classifies Polyester shorts and wool socks, and

the polyester band on the wool socks.

Some textile datacubes are available on downloads.resonon.com. You can

download a free copy of Spectronon™ and the datacubes there.

For this case study, securing an adequate training sample

set was more time-consuming than the study itself. It took less than 30 minutes

to scan samples, train a classification model, and start classifying textiles

with SpectralSight™.

To further advance this preliminary textile sorting system,

the next step would be to train the RVS software with more samples,

representative of the wide variety of existing textiles including blends like cotton/polyester

and wool/acrylic.

Nonetheless, based on the success of this study, it is safe

to conclude that textile sorting devices that utilize hyperspectral imaging

will be robust, accurate, and reliable.

Contact Resonon

to discuss your application and how we can help you solve challenges with

hyperspectral imaging.

References

- https://www.epa.gov/facts-and-figures-about-materials-waste-and-recycling/textiles-material-specific-data

- https://environment.ec.europa.eu/strategy/textiles-strategy_en

- https://environment.ec.europa.eu/document/download/74126c90-5cbf-46d0-ab6b-60878644b395_en?filename=COM_2022_141_1_EN_ACT_part1_v8.pdf

- https://www.reuters.com/sustainability/eu-wants-all-textile-waste-rules-place-by-2028-commissioner-2023-06-27/

- https://earth.org/statistics-about-fast-fashion-waste/

- https://www.europarl.europa.eu/topics/en/article/20201208STO93327/the-impact-of-textile-production-and-waste-on-the-environment-infographics

- https://www.nationalgeographic.com/environment/article/chile-fashion-pollution (source of Header image)

Contact us

Contact usMore Case Studies

Contact Us

Click below and our hyperspectral experts will contact you soon.

Complete Hyperspectral Imaging Solutions

Contact

Resonon Inc.123 Commercial Drive

Bozeman, MT 59715 USA